Solution Recommendations

Excellent defoaming property, maintain the comfortable handle

Decision's recommendation of optimal product of DESOPON SK70

What are foams?

They are magic floating above the rainbows;

They are the charming glow on the hair of our loved one;

They are the trails left behind when a dolphin dives into the deep blue ocean…

To tanners, foams are caused by mechanical treatments (inside the drums or by paddles), that encapsulated air inside the surfactant components of the working fluid and formed a mixture of gas and liquid.

Foams are inevitable during the wet end process. That is because, in the wet end process, especially the retanning stage,water, surfactants and mechanical treatments are the three main factor of the cause of foams, yet these three factors exist nearly throughout the process.

Amongst the three factors, surfactant is one of the essential materials used during the tanning process. The uniform and stable wetting of crust and the penetration of chemicals into the crust all depend on it. However, a substantial amount of surfactant could cause the problems of foams. Too much foams could bring about problems for the proceeding of the tanning process. For instance, it might affect the even penetration, absorption, fixation of chemicals.

DESOPON SK70

Excellent defoaming performance

DESOPON SK70 is ‘the invincible lifesaver’ in the tanning process, when large amount of foams are produced, its defoaming ability quickly and effectively helps the working fluid to turn back to its original state, and helps create a stable, even and highly effective structure, in order to ensure the stability, evenness and the brilliant and uniform dyeing effect of the crust

However, if you think DESOATEN SK70 is just like any other fatliquors with defoaming property, then you are absolutely underestimating it. Because, like we have just mentioned a while ago, it is an ‘invincible lifesaver’!

DESOPON SK70

Ability of maintaining good hand feel

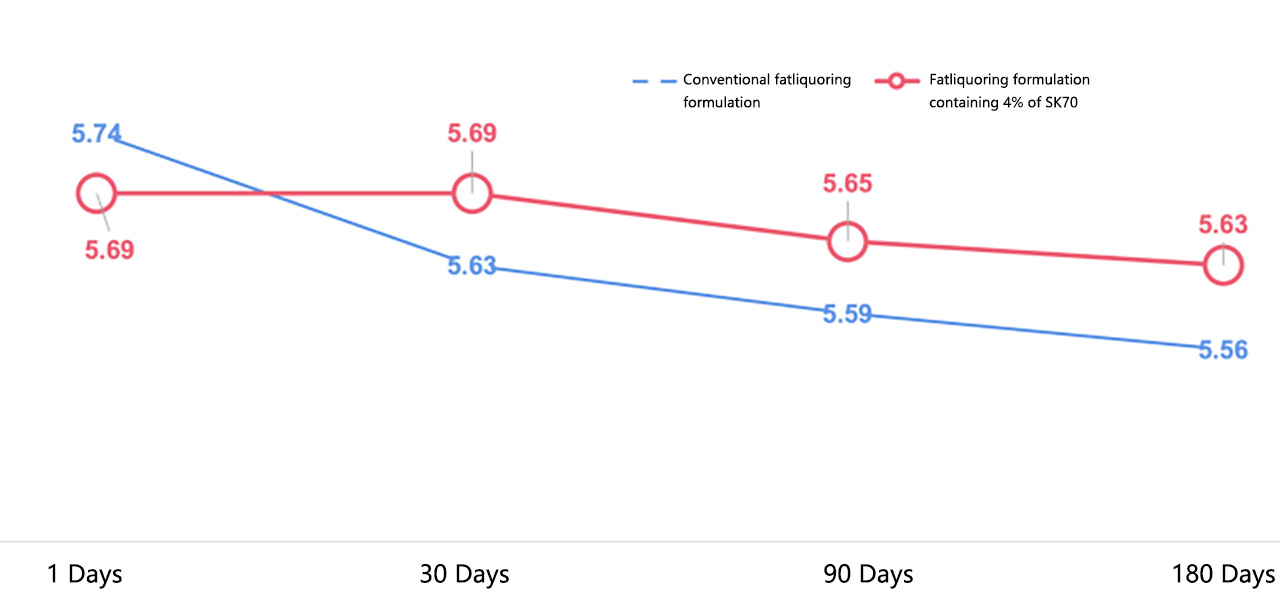

As we already know, that one of the main functions of fatliquors is to provide the crust with needed softness. For most crusts after drying process, its softness is usually tested(manually or by using instrument) ,the testing is usually done right after the drying process. In fact, some technicians have noticed that the degree of softness of crust decreases over time.

For instance, the crust tested three months later is harder than the crust three months ago. (sometimes it is unremarked because the crust after being tested would go through a series of finishing process.)

It isn’t hard for a fatliquor product to be able to make the crust soft and flexible, what is difficult is to help maintain the softness and resilience of the crust for a long period of time.

Just like the art of tanning, the key point to achieving effective tanning technology is being continuously beneficial to the tanning process, to the leather and to the tannery.

In regard to this problem, through our long period of storage of the samples and repeated tests, it has been confirmed that the crust samples after using DESOPON SK70 has a tendency of improvement in softness

over a period of time:

With further tests, by adding DESOPON SK70 during tanning process, the maintenance of the softness of crust has also improved markedly:

/great handle

/outstanding aging-fastness

/good fixing ability

/brilliant dyeing effect

/excellent maintenance of good handle

/effective defoaming performance

etc……

Decision will continue with the research and development of sustainable leather chemical materials. We will keep exploring from diversified angles, the physicochemical properties of different materials when used on leather and the sensory effect of the leather after using certain products. We have faith that ‘concentration and devotion’ will generate productivity, we are also looking forward to your needs and feedback.

Sustainable development has become a very important part in the leather industry, the road to sustainable development is yet long and full of challenges.

As a responsible enterprise we will carry this as our obligation and work persistently and indomitably towards the final goal.

Explore more