Solution Recommendations

Every rainy day, many children's favorite thing to do is to go out and adventure, each small cesspool is a need to be conquered "ocean", wearing rain boots to step out of the splash pace, the joy of children is always simple and beautiful, which is probably also a lot of childhood memories of adults.

If it's raining now, will you still be willing to put on the pair of rain boots you remember? Have a close contact with the water?

If your answer is yes, then outdoor shoes made with waterproof leather may be more suitable for you than stuffy and non-breathable plastic rain boots (not outdoor shoe ads).

The special dynamic waterproof performance of waterproof leather compared to ordinary leather can meet the needs of some special leather products, such as outdoor shoes, labor protection shoes and military leather products.

The production of waterproof leather requires relatively special process control and waterproofing agent products. In order to get excellent dynamic waterproofing ability, not only high performance waterproofing agent products (mainly waterproofing fatliquor) are needed, but also they need to be evenly and deeply distributed in the leather.

Therefore, it is very necessary to improve the penetration and dispersion of tanning agents, especially water repellents, but the conventional dispersion of tannin and surface active products for waterproof leather is a big taboo, improper use will lead to waterproof performance can not meet the requirements.

After DECISION's technical research and development team's in-depth research and repeated tests.

Introduced our protagonist today:

Multifunctional polymer additive DESOATEN RD

A polymer additive with high dispersion capacity

For the production of waterproof leather

The multifunctional polymer additive DESOATEN RD can be used as a rewetting and neutralizing additive in the waterproof leather process and as a dispersant for waterproof oil, resulting in a high performance waterproof leather.

The multifunctional polymer additive DESOATEN RD shows its versatility in the production of waterproof leather, and then the story doesn't end there ......

Multifunctional polymer additive DESOATEN RD as a polymer dispersant, due to its special structure, used in conventional processes, presents more properties compared to conventional naphthalene sulfonate dispersants and conventional surface active products:

• The polymer carboxyl group tends to fix chromium, which can get relatively fuller and tighter elastic leather

•Better yellowing resistance and brighter dyeing effect

•Better fattening properties and excellent neutralizing properties.

Comparison of DESOATEN RD with conventional emulsifier products

Excellent ability to emulsify grease

*Reduced grease fixation compared to conventional emulsifiers

The polymer will instead help the final fixation of the grease.

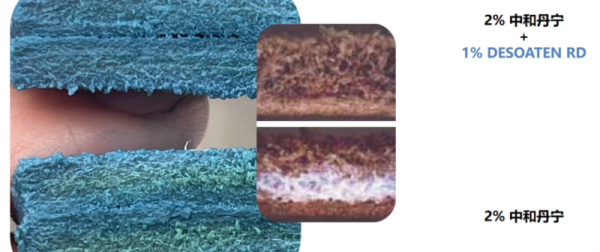

Comparison of the penetration effect of DESOATEN RD

Excellent effect on penetration of neutralization.

In summary

DESOATEN RD is a versatile all-rounder in the tanning process with many more properties and advantages!

Sustainable development has become a very important part in the leather industry, the road to sustainable development is yet long and full of challenges.

As a responsible enterprise we will carry this as our obligation and work persistently and indomitably towards the final goal.

Explore more